Commercial spray foam helps Raleigh warehouses regulate indoor temperatures by creating a continuous, high-performance insulation layer that blocks unwanted heat gain and air movement. In large industrial spaces, managing indoor climates can be costly and inconsistent. Spray foam forms an airtight thermal envelope that reduces reliance on heating and cooling systems while controlling humidity levels.

This insulation approach is particularly effective in Raleigh, where warehouses face seasonal humidity, heat waves, and cold snaps. The expanding nature of spray foam allows it to seal structural gaps, roof joints, and wall cavities that traditional insulation methods often miss. This article explains how commercial spray foam works, where it fits into warehouse design, and what to consider before choosing it as a long-term insulation solution.

Types of Commercial Spray Foam Used in Warehouses

Two primary types of spray foam are used in commercial settings: open-cell and closed-cell. Their physical structure, insulation strength, and application suitability differ based on building requirements and performance goals.

Comparison of Open-Cell vs Closed-Cell Spray Foam

| Feature | Open-Cell Foam | Closed-Cell Foam |

| Cell Structure | Soft, semi-rigid | Dense, rigid |

| R-value per inch | ~3.6 | ~6.5 |

| Water Resistance | Low | High |

| Air Sealing Ability | Moderate | Excellent |

| Moisture Barrier | No | Yes |

| Structural Reinforcement | Minimal | Adds rigidity |

| Acoustic Insulation | Excellent | Moderate |

| Installation Cost | Lower | Higher |

| Ideal Use | Interior walls, ceilings | Exterior walls, roofs |

Bonus Tip

Bonus Tip

Use open-cell spray foam for sound attenuation in interior office partitions within the warehouse, and closed-cell foam for external envelope insulation.

Technical Performance Metrics

The following technical data helps illustrate how spray foam performs in the demanding environments of commercial warehouses:

| Specification | Closed-Cell Foam Value | Relevance for Warehouses |

| R-Value (per inch) | 6.0–7.0 | Superior thermal insulation |

| Vapor Permeability | <1 perm | Moisture and humidity control |

| Compressive Strength | ~25 psi | Adds durability to wall systems |

| Air Leakage Rate | Near-zero | Eliminates drafts and energy loss |

| Application Temperature | 40°F to 120°F | Suitable for year-round installs |

| Lifespan | 30–50 years | Long-term energy savings |

Why Temperature Control Matters in Raleigh Warehouses

Why Temperature Control Matters in Raleigh Warehouses

Climate Pressures in Raleigh

Raleigh has a humid subtropical climate with summer highs exceeding 90°F and winter lows in the 30s. Warehouses, particularly those with metal frames and unconditioned spaces, are prone to:

- Excessive heat buildup under metal roofing

- Condensation forming on cold surfaces

- Uneven interior temperatures between occupied and storage areas

Commercial spray foam mitigates these problems by regulating the heat flow across the building envelope. It acts as both an insulator and air barrier, maintaining interior comfort year-round.

Impact on Energy Efficiency

Poor thermal control forces HVAC systems to work harder. According to the U.S. Department of Energy, 30–40% of energy loss in commercial buildings is due to air leakage and inadequate insulation. Closed-cell spray foam directly addresses this by:

- Preventing conductive and convective heat loss

- Lowering peak demand on cooling systems in summer

- Maintaining consistent heating during cold spells

Bonus Tip

In multi-zone warehouses, use spray foam to isolate climate-sensitive zones such as temperature-controlled storage or packaging areas.

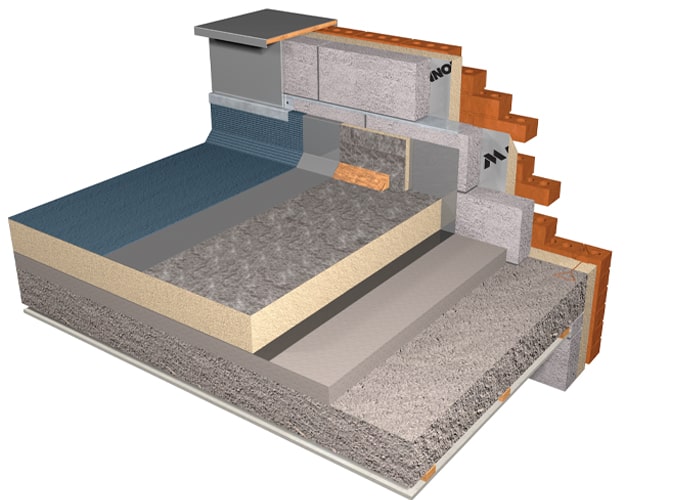

Application Areas Inside Warehouses

Rooflines and Ceiling Decks

These areas receive the most solar exposure. Spray foam blocks radiant heat transfer and prevents thermal bridging across structural elements.

Wall Cavities

Foam injected into metal or concrete wall assemblies creates a uniform insulation layer that eliminates gaps and seams.

Floor-to-Wall Transitions

Often overlooked, these joints leak conditioned air. Spray foam seals them tightly to prevent unwanted airflow.

Loading Docks and Doors

Openings cause heat gain and loss during operations. Foam around dock seals and door frames improves thermal retention.

Installation Process for Commercial Use

Spray foam application follows a systematic process to ensure coverage and performance:

- Initial Assessment

Evaluate building design, exposure zones, HVAC load, and existing insulation. - Surface Preparation

Clean, dry, and prep surfaces to ensure proper adhesion. - Layered Application

Spray foam is applied in thin layers, allowing expansion and curing before the next pass. - Post-Installation Inspection

Verify coverage, adhesion, and thickness using thermal imaging or core sampling. - Fire Protection Compliance

Install thermal or ignition barriers where required by local building codes.

Bonus Tip

Always consult with a certified spray foam contractor to ensure compliance with Raleigh’s specific commercial insulation codes.

Things to Consider Before Making a Decision

Choosing the right insulation method for your warehouse involves evaluating structural, operational, and regulatory factors:

- Building Code Requirements

Raleigh follows North Carolina Energy Conservation Code (NCECC), which mandates minimum R-values and fire safety compliance. - Ventilation Needs

Air-sealed buildings may require mechanical ventilation systems to maintain indoor air quality. - Structural Compatibility

Verify that foam is compatible with existing building materials, especially in retrofit projects. - Moisture Risk

Closed-cell foam is preferred in areas prone to moisture intrusion or high humidity. - Long-Term ROI

Although more expensive upfront, spray foam’s energy savings often lead to a payback within 3–7 years.

Common Questions

Is spray foam suitable for metal warehouses?

Yes. Closed-cell foam adheres well to metal panels, providing insulation and moisture protection without compromising structural integrity.

Can it be installed over existing insulation?

Yes, but existing material must be dry, stable, and free of contaminants to ensure proper bonding.

How long does the installation take?

A typical 50,000 sq. ft. warehouse can take 3–5 days depending on the number of installers and prep complexity.

Does it eliminate condensation?

Closed-cell spray foam controls condensation by reducing dew point contact on interior surfaces.

Topic FAQ

What makes spray foam more effective than fiberglass in warehouses?

Spray foam creates a seamless air and moisture barrier, unlike fiberglass which allows airflow and loses performance when wet.

Can it be used in retrofit applications?

Yes. Spray foam is often used in upgrades where existing insulation fails to meet thermal performance or air sealing needs.

Is spray foam affected by Raleigh’s humidity?

No. Closed-cell foam resists moisture intrusion and does not degrade in humid conditions.

Does it provide sound insulation?

Open-cell spray foam offers excellent sound dampening for office zones and internal partitions.

Is maintenance required?

Spray foam requires minimal maintenance once installed. Routine inspections can confirm long-term performance.

Make the Right Decision

In Raleigh’s demanding climate, commercial spray foam helps warehouse operators control temperature, reduce energy bills, and stabilize interior conditions. Its high R-value, air sealing capabilities, and long service life make it a preferred solution over traditional materials. Before investing, assess your building’s structure, code requirements, and long-term efficiency goals. Done correctly, spray foam is not just insulation—it’s a strategic upgrade for warehouse performance.