Closed cell insulation significantly boosts energy efficiency in Crockett, TX by creating an airtight thermal barrier that reduces heating and cooling costs by 30-50%. The dense structure of closed cell foam (2.0-2.5 pounds per cubic foot) provides an exceptional R-value of 6.5-7 per inch—nearly twice that of traditional insulation materials—while simultaneously blocking air infiltration and moisture penetration. This comprehensive approach to building envelope performance addresses the specific challenges of Crockett’s climate, where hot, humid summers and occasionally cold winters demand consistent thermal regulation.

Property owners in Crockett who install closed cell insulation typically recoup their investment within 3-5 years through reduced energy bills, with savings continuing throughout the insulation’s 30+ year lifespan. Beyond energy savings, closed cell insulation strengthens structural integrity, prevents moisture-related issues common in Texas, and creates healthier indoor environments by blocking airborne contaminants and reducing noise transmission.

How Closed Cell Insulation Works

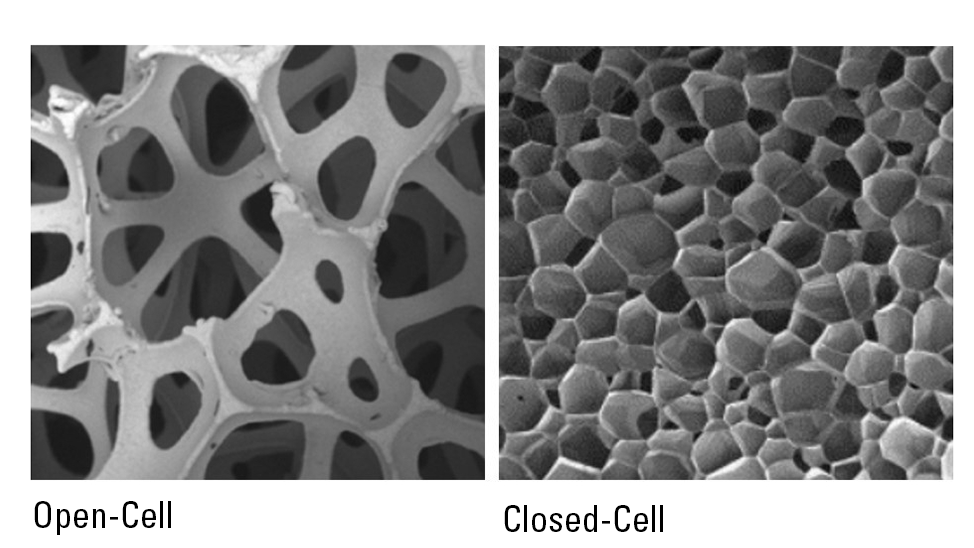

Closed cell insulation functions through a unique cellular structure where individual cells are completely sealed from neighboring cells, creating a dense material filled with inert gas. This structure blocks all three forms of heat transfer: conduction (direct heat flow through materials), convection (heat transfer through air movement), and radiation (heat transfer through electromagnetic waves).

When professionally applied, the liquid components react and expand to form a rigid foam that adheres strongly to surfaces and fills gaps, cracks, and voids. This expansion process creates a continuous insulation layer without the seams or gaps inevitable in traditional insulation systems. The result is a comprehensive thermal envelope that maintains indoor temperatures with minimal energy input.

The high-density nature of closed cell foam provides structural benefits beyond insulation. Once cured, the material adds rigidity to walls, roofs, and other building components, potentially increasing wind resistance by up to 300% in properly designed applications.

Performance Comparison of Insulation Types

Performance Comparison of Insulation Types

| Insulation Type | R-Value Per Inch | Air Barrier | Moisture Barrier | Structural Enhancement | Typical Lifespan | Energy Savings Potential |

| Closed Cell Spray Foam | 6.5-7.0 | Excellent | Excellent (Class II vapor retarder) | Significant | 30+ years | 30-50% |

| Open Cell Spray Foam | 3.5-3.9 | Very Good | Poor (vapor permeable) | Minimal | 20+ years | 20-30% |

| Fiberglass Batts | 2.9-3.8 | None | None | None | 10-15 years | 10-20% |

| Cellulose | 3.1-3.8 | Fair | Fair | None | 15-20 years | 15-25% |

| Rigid Board (EPS) | 3.6-4.2 | Poor (at seams) | Good | Minimal | 20+ years | 15-25% |

| Mineral Wool | 3.0-3.3 | None | Good | None | 20+ years | 15-20% |

Technical Specifications of Closed Cell Insulation

| Property | Standard Value | ASTM Test Method | Performance Impact |

| Density | 2.0-2.5 lb/ft³ | D1622 | Higher density correlates with higher R-value and strength |

| R-Value | 6.5-7.0 per inch | C518 | Higher values provide better thermal resistance |

| Compressive Strength | 25-30 psi | D1621 | Adds structural integrity to building components |

| Closed Cell Content | >90% | D6226 | Higher percentage improves moisture and air resistance |

| Water Absorption | <2% by volume | D2842 | Lower values indicate better moisture protection |

| Water Vapor Permeance | <1.0 perms at 2″ | E96 | Lower values indicate better vapor control |

| Air Permeance | <0.004 L/s-m² at 1″ | E2178 | Lower values indicate better air sealing capability |

| Dimensional Stability | <2% volume change | D2126 | Lower values indicate better long-term performance |

| Sound Transmission | STC 37-45 at 2″ | E90 | Higher values indicate better sound blocking |

| Fire Rating | Class A with proper coating | E84 | Meets building code requirements |

Climate-Specific Benefits for Crockett, TX

Crockett’s location in Texas creates specific energy efficiency challenges that closed cell insulation addresses effectively. The region experiences hot, humid summers with temperatures regularly exceeding 95°F and humidity levels above 75%, along with periodic cold snaps in winter that can drop below freezing.

Market data from the Texas region shows buildings with closed cell insulation maintain more consistent internal temperatures with 30-40% less HVAC runtime compared to buildings with traditional insulation systems. According to regional energy audits, this typically translates to $0.50-$0.75 per square foot in annual energy savings for most commercial and residential structures.

The specific energy advantages for Crockett properties include:

- Superior humidity control through vapor barrier properties, reducing the latent load on air conditioning systems

- Consistent thermal performance during temperature extremes, preventing spikes in energy usage

- Prevention of solar heat gain during intense summer months

- Elimination of cold spots and drafts during winter cold fronts

BONUS TIP: In Crockett’s climate, proper installation thickness is crucial. While building codes may specify minimum R-values, increasing closed cell foam thickness by an additional inch can provide disproportionately higher energy returns, often adding only 15-20% to installation costs while boosting performance by 25-30%.

Application Areas for Maximum Efficiency

Closed cell insulation delivers energy benefits throughout a building envelope, but strategic application maximizes return on investment in Crockett’s specific climate conditions:

Roof and Attic Spaces

Applying closed cell foam directly to the roof deck creates a sealed attic that dramatically reduces energy loss where it typically occurs most. This approach:

- Lowers attic temperatures by 30-40°F during summer months

- Prevents radiant heat transfer to living spaces

- Protects HVAC equipment and ductwork often located in these spaces

- Creates dry, usable storage space without energy penalties

In Crockett’s climate, properly sealed and insulated attics with closed cell foam typically reduce whole-building energy usage by 15-25% compared to conventionally insulated attics.

Wall Assemblies

Closed cell insulation in exterior walls provides comprehensive thermal protection while addressing moisture concerns common in humid Texas. The material:

- Fills irregular cavity spaces completely

- Prevents air infiltration at joints and penetrations

- Blocks moisture drive into wall assemblies

- Adds structural rigidity to the building frame

Crawlspaces and Foundations

Crawlspaces and Foundations

Applying closed cell insulation to crawlspaces and foundations addresses often-overlooked energy loss points while preventing moisture problems:

- Reduces floor temperature differentials

- Prevents ground moisture from entering the building

- Eliminates a major source of humid air infiltration

- Protects plumbing from freezing during cold snaps

Energy Return on Investment Analysis

When evaluating closed cell insulation as an energy efficiency investment in Crockett, consider both immediate and long-term financial impacts:

Initial Investment vs. Energy Returns

The initial cost for closed cell insulation in the Crockett area typically ranges from $1.50-$2.50 per board foot (one square foot at one inch thickness), depending on project complexity and access. While this exceeds traditional insulation costs, energy savings typically provide payback within:

- Commercial buildings: 3-4 years

- Residential structures: 4-5 years

- Industrial facilities: 2-3 years

According to regional energy studies, closed cell insulation delivers approximately 25-30% better energy returns than equivalent investments in other efficiency upgrades like window replacements or HVAC system enhancements.

Extended Financial Benefits

Energy savings continue throughout the insulation’s 30+ year lifespan, generating significant returns beyond the initial payback period. Additional financial advantages include:

- Potential downsizing of HVAC equipment (10-20% smaller units)

- Extended HVAC equipment lifespan due to reduced runtime

- Elimination of costs associated with moisture-related repairs

- Increased property value (energy-efficient buildings typically command 4-7% higher values)

BONUS TIP: Coordinate closed cell insulation installation with other renovation projects to reduce overall costs. For example, if roof work is already planned, adding closed cell insulation at the same time eliminates duplicate labor costs and access expenses.

Things to Consider Before Making a Decision

When evaluating closed cell insulation for energy efficiency in Crockett, several factors warrant careful consideration:

Building Assessment Factors

The effectiveness of closed cell insulation depends on proper application according to building-specific conditions:

- Current insulation status and performance gaps

- Building air leakage rates and primary infiltration points

- Moisture control requirements based on building use

- Structural considerations for adding material weight

A comprehensive building assessment can identify the optimal application areas for maximum energy return while addressing hidden issues that might compromise performance.

Installation Considerations

Professional installation significantly impacts energy performance:

- Proper substrate preparation ensures adhesion and coverage

- Temperature conditions during application affect foam quality

- Equipment calibration ensures consistent density and R-value

- Surface access requirements may affect project complexity

Ventilation Requirements

The airtight seal created by closed cell insulation necessitates planned ventilation:

- Mechanical ventilation may require upgrading

- Combustion appliances may need makeup air provisions

- Indoor air quality considerations become more important

Code and Compliance Factors

Local building codes in Crockett and surrounding areas govern installation:

- Fire barrier requirements vary by building type

- Minimum R-value requirements by assembly type

- Vapor barrier positioning based on assembly design

- Thermal barrier requirements for exposed applications

Common Questions About Closed Cell Insulation

Energy Performance Timeline

Most buildings see immediate temperature stability improvements after installation, with energy bill reductions visible within the first full billing cycle. Maximum efficiency is typically reached within 30-60 days as the building achieves temperature equilibrium and HVAC systems adjust to reduced loads.

System Compatibility

Closed cell insulation works with all standard HVAC systems and often improves their performance by reducing the load demands. Existing systems may require rebalancing after installation to optimize for the new thermal envelope characteristics.

Retrofit Applications

Closed cell insulation can be added to existing buildings without complete renovation in many cases. Strategic application to accessible areas like attics, crawlspaces, and rim joists often delivers 50-70% of the energy benefits of whole-building treatment at substantially lower cost.

Environmental Considerations

While the installation process requires careful management of chemicals, the long-term environmental impact is positive through reduced energy consumption. Modern closed cell formulations use water-blown technology with zero ozone depletion potential and low global warming potential.

FAQ

How much energy will I actually save with closed cell insulation in Crockett?

Most buildings in the Crockett area experience 30-50% reductions in heating and cooling costs after proper closed cell insulation installation. A typical 2,000 square foot residence often saves $800-$1,200 annually on utility bills, while commercial buildings may see $0.50-$0.75 per square foot in energy cost reductions. Actual savings depend on building condition, usage patterns, and existing insulation status.

Does closed cell insulation work better than other insulation types in our humid climate?

Yes, closed cell insulation performs exceptionally well in Crockett’s humid climate due to its moisture-resistant properties. Unlike traditional insulation that can absorb moisture and lose effectiveness, closed cell foam maintains its R-value even in high humidity conditions. Its vapor barrier properties also prevent condensation issues common with other insulation types in Texas weather patterns.

How long will closed cell insulation maintain its energy efficiency benefits?

Quality closed cell insulation maintains its energy efficiency properties for 30+ years with minimal degradation. Unlike traditional insulation materials that can settle, compress, or absorb moisture over time, closed cell foam retains its structure and thermal resistance properties throughout its lifespan, providing consistent energy savings for decades.

Will closed cell insulation help with the temperature fluctuations we experience in Crockett?

Absolutely. Closed cell insulation excels at maintaining stable indoor temperatures despite outdoor fluctuations. Its high R-value and air sealing properties create a thermal buffer that substantially reduces the impact of Crockett’s temperature swings, which can exceed 30°F within a single day during transitional seasons. This stability reduces HVAC cycling and improves occupant comfort while lowering energy bills.

Is closed cell insulation worth the higher upfront cost compared to traditional insulation?

For most Crockett properties, the answer is yes. While closed cell insulation costs more initially than traditional options, its superior performance in our specific climate conditions delivers a return on investment typically within 3-5 years. When factoring in additional benefits like moisture control, increased structural strength, and longer lifespan, closed cell insulation usually provides better long-term value despite the higher initial investment.

Ready to Achieve Superior Energy Efficiency?

Closed cell insulation offers Crockett property owners a proven solution for substantial, long-lasting energy savings. By creating a comprehensive thermal envelope that addresses both conductive heat transfer and air infiltration, this technology delivers superior performance in Texas’s challenging climate conditions.

Apply these insights now: Schedule your comprehensive energy assessment with D&D Insulation LLC to identify the optimal application areas for closed cell insulation in your specific building. Their expertise in local climate conditions ensures you’ll receive an accurate analysis of how closed cell insulation can reduce your energy costs while improving comfort.

Contact D&D Insulation LLC at (903) 389-5705 or [email protected].

Reviewer

Henry Turner has 9 years of experience in spray foam insulation. He reviewed this article and helped shape it into a clear guide for companies working to build trust in their local market.